About the company

LTD “S. S. P.” is located in the center of Odessa region on the south of Ukraine, in 20 km from marine ports of Ukraine – Chernomorsk Merchant Sea Port (IMSP) and Odessa Sea Port (OSP).

The main activity of the factory is a production of seed of wheat, barley, peas, millet and flax, including the complete cleaning on the seed line of AKY production (Turkey), certification, packing in 1 ton Big-Bags or the bags of 40kg, for selling to the agricultural producers for trading sowing.

As main suppliers of seed materials for our company come forward SAATBAU LINZ, SAATEN-UNION, OSEVA, etc. Growing of the seed is carried out by our partners, based on the technical recommendations provided by us, under the supervision of our agronomists.

Additionally, the specialists of the company provide with agronomical support and supervision the clients, who use our seeds starting from the sowing till the harvesting.

Stages of production

Stages of production

Stage one: Sorts selection

Stage one: Sorts selection

We select for the reproduction the best sorts from European breeders, who have the highest results of the harvest, winter and draught resistance, and are highly resistant to the illnesses.

Stage two: Reproduction areas selection

Stage two: Reproduction areas selection

We priorities in the selection the farmlands, which follow the high standards of production, have the modern equipment, and are responsible for the technical processes of crops cultivation.

Stage three: Control of seed cultivation

Stage three: Control of seed cultivation

- Selection of the farmlands with taking into account the predecessor, which is optimally suitable for the cultivation of the seed sort;

- Calculation of the optimal seeding rate for each sort. The rate is calculated on the basis of the recommendations of the originators and their own experience gained on experimental farmlands, as well as commercial sowing

- For each sowing land we develop a technological map for plant nutrition, taking into account the technological capabilities and technical equipment of the farm

- Our agronomists constantly monitor the phyto-, entopathological state of crops by visiting the fields, as well as using agronomic apps

- While required, we perform the weeding of seed lands, both based on type and sort

Stage four: Approbation

Stage four: Approbation

It is performed with the participation of our agronomists who is certified by seed inspection specialists for confirmation of the varietal purity of seed lands.

Stage five: Harvest

Stage five: Harvest

Control over the correct conduct of this technological operation, mowing and tilling of crops with the separation of the grains for commercial purposes. Cleaning and “flushing” of the combine is performed before harvesting each individual sort of different crops, with is separated by generations. Storage of each sort and generation in separate piles, preventing any mixing.

Stage six: Receiving the seed heap

Stage six: Receiving the seed heap

The heap which is arriving at the factory is divided into incoming parts separately for each crop, sort, generation and area of breeding.

Stage seven: Preliminary cleaning

Stage seven: Preliminary cleaning

The pre-cleaning machine removes large plant residues remaining with a heap of grain (straw, unmilled ears, large stones, large weeds) and small debris (crushed grain, dust and small weeds)

Stage eight: Calibration

Stage eight: Calibration

The calibration machine separates the grains with the greatest possible mass, the same size, fully formed and meeting the requirements for the seed. The rest of the grain that does not meet these requirements is used for the fodder.

Stage nine: Stone separation

Stage nine: Stone separation

After preliminary cleaning and calibration, small stones that are the size of seeds are removed on the stone separator.

Stage ten: Fine cleaning

Stage ten: Fine cleaning

Fine cleaning is performed on equipment with three levels of sieves and powerful aspiration, as well as with the connection of a trier unit and a gravity table, which allow to separate all types of weeds and grain impurities.

Stage eleven: Packaging

Stage eleven: Packaging

Is performed automatically on electronic scales, in big bags with the company logo, which weight one tonne, and their further sealing.

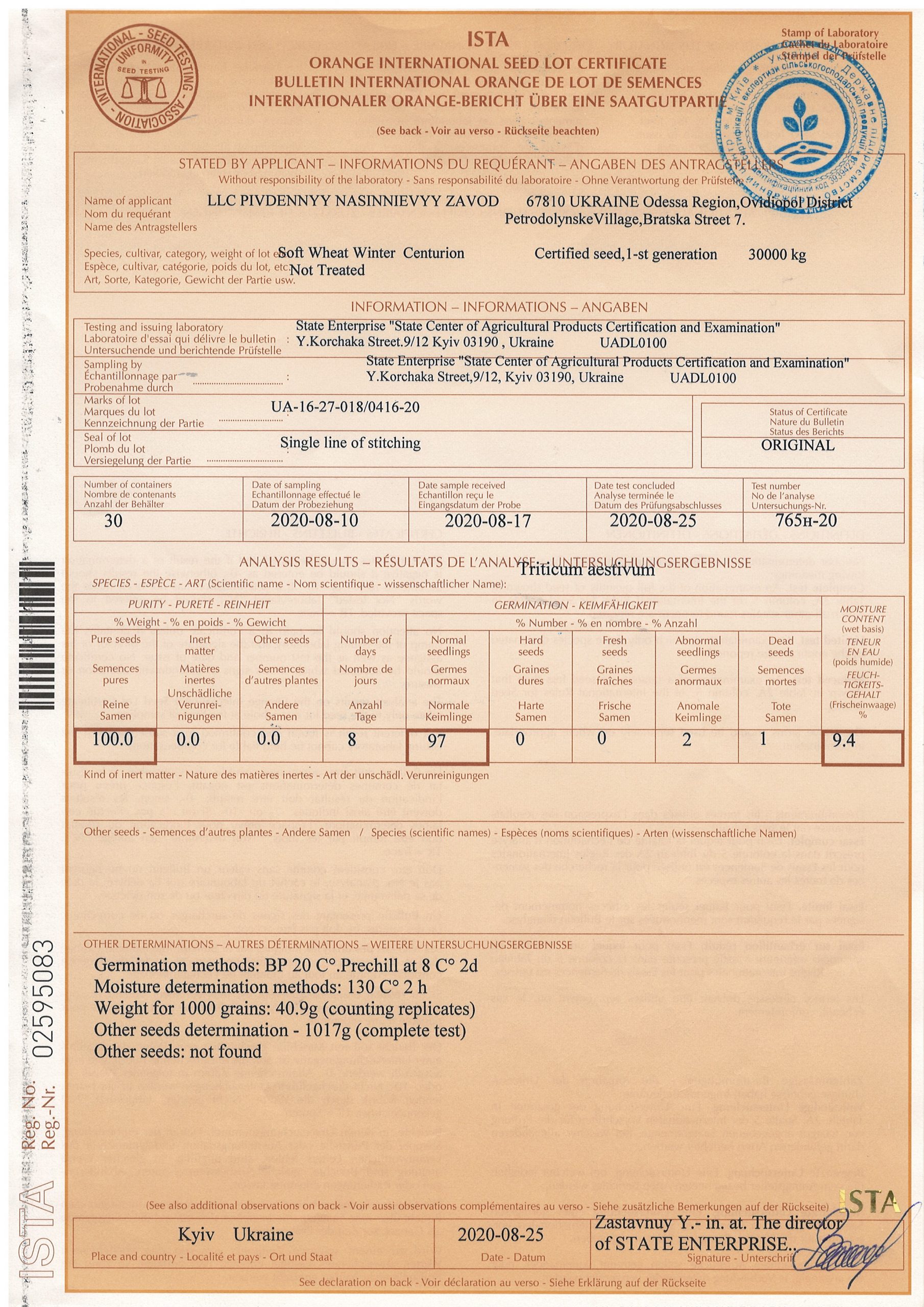

Stage twelve: Certification

Stage twelve: Certification

With each batch of seeds, an accredited inspector takes samples for delivery to a certified laboratory, where the sowing qualities are determined, as well as their compliance with the current norms and requirements.

Stage thirteen: Seeds shipment

Stage thirteen: Seeds shipment

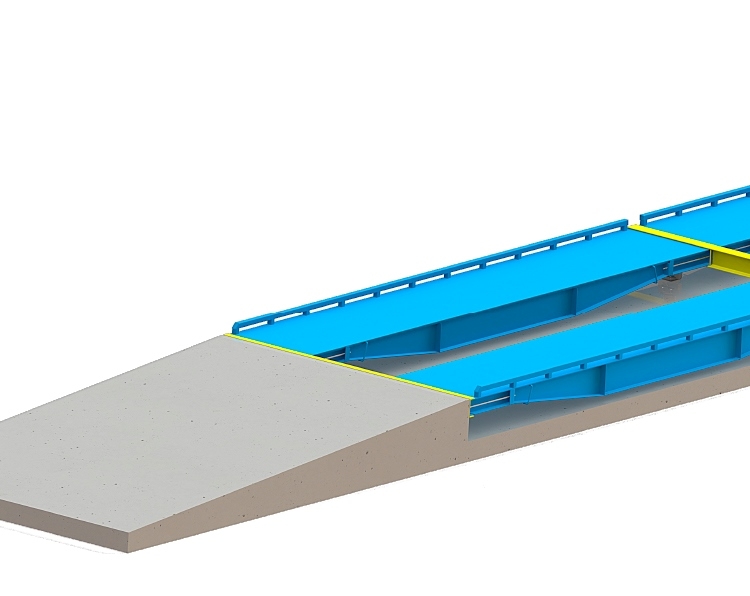

Is performed at the factory in the transport that meets the requirements of the current rules and transportation regulations of grains in big bags. To control the total weight, an 80-tonnes electronic scale is installed at the factory.